This will let you use the bottom of the workpiece. In order to keep the molten weld pool from piling in this position, you need to make sure that your flame is pointed upwards and tilted at 45 degrees to your base metal. You can prevent this by using a downhill or upward vertical position when you weld. When you use these positions, gravity will try to force your molten metal downwards, which causes it to pile up in one spot of your point instead of getting evenly distributed along the entire weld. Position, which are a vertical groove and vertical fillet weld respectively. You will use positions 3G and 3F for this weld The actual welding you will need toĭo is horizontal instead. Positioned vertically or nearly vertically. With vertical welding, your weld’s axis will typically be You can control the size of your weld bead by changing up your welding speed and how much metal you’re dropping in from the rod. Yur rod will then be placed into the puddle, which will melt the base metal to the rod.įor proper fusion between the two pieces of metal being joined, you need to move your torch very slowly side to side. When you use a welding rod to form your beads, you need a small puddle on the surface.

Your weld puddle needs to stay as small as you can keep it, otherwise, you could end up burning through your base instead! If you need a deeper weld for added strength, you need to decrease the speed you’re welding at or increase the severity of the angle between your tip and base metal. Creating narrow beading requires you to raise then lower your flame in a circular motion, which will distribute heat evenly.Ī 45-degree angle is the best way to position your top as it approaches the base metal’s surface. Your torch will need to be perfectly set for the flame you will need on your specific base metal. In order to get beautiful weld beads when working from a flat position, you will need to make sure you maintain the flare motion, tip angle, and position of your flame. Side Note: If someone refers to the downward position in welding, they are talking about this flat weld position. This weld is quick, simple, and very strong. This technique allows you to move your molten metal pool downward so that it can fill the joint. It’s the easiest position to learn and work with because the weld pool is able to lay flat and be manipulated in any direction you want to move.įor this position, you will be welding from the top side of the joint, with the face of the joint in a horizontal position. The flat welding position is a dream come true. They are considered out of position because these positions require more skill and technique. If you hear that something requires you to weld out of position, it could refer to any position except for the flat weld position, usually horizontal, overhead, and vertical. When someone mentions the axis of any welding project, they are referring to an imaginary line that goes through the length of the weld in a perpendicular direction to the cross at the center of gravity.

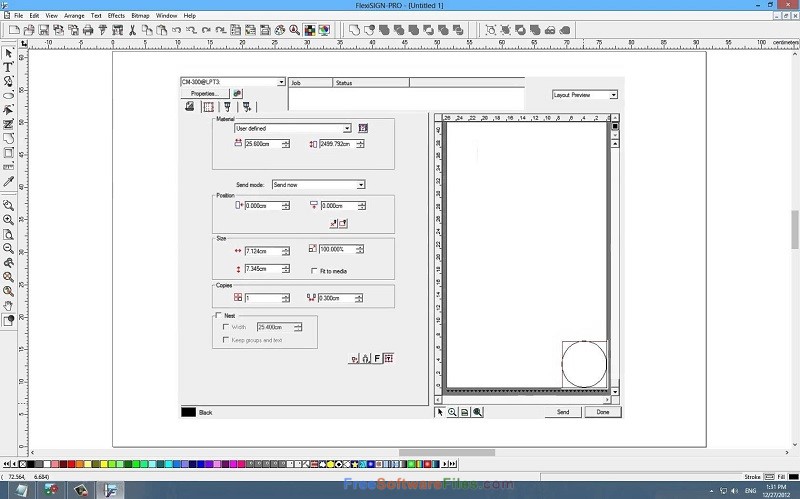

#How to weld letters in flexisign 12 how to#

Let’s break them down into more detail now, so you know when and how to use each different position and technique. There are different instances where you will need to make use of each of these positions. The 5 basic MIG welding positions all offer different challenges and strengths. Start with the easier positions and slowly work your way towards the more complicated ones as you begin mastering proper technique and learning to control your weld pool and heat.

We cover when you use each position, how it works, and even comprehensively discuss the pipe welding positions, which are technically 1 of the 5 but have their own set of rules entirely from the other MIG welding positions.īy the end of this article, you will be ready to grab those charts and interpret the positions! Just remember that although theory is easy to understand, the application can be very difficult and dangerous. What are the 5 welding positions? The 5 major welding positions are flat weld, vertical weld, horizontal weld, overhead weld, and pipe welds. These symbols often involve a number 1-4 and a letter, F or G, that denotes the position you will use. These positions employ a variety of techniques and comprise the 8 different weld symbols you will often see on charts and how-to guides. With MIG welding, there are 5 basic welding positions. However, over time learned a lot of things from the types of welds to the actual welding positions that you need to make. Back nearly 20 years ago when I was first getting started with MIG welding I knew that you basically pointed the welding gun at the spot that you wanted to weld and pulled the trigger.

0 kommentar(er)

0 kommentar(er)